Reconditioning a final drive

VTS Track Solutions offers next to new, also reconditioned final drives. After reconditioning, the final drives are tested and delivered with a test certificate including warranty. This assures the reliability of the repaired product for a low investment.

When a customer delivers a used final drive to VTS we start one of the following 3 processes:

- Regular reconditioning

- Claim

- Exchange

Regular reconditioning means that an old final drive is repaired to its working state. Defect or worn out parts are replaced.

A claim means that a new final drive seems to be defect and the customer still has warranty on the product. VTS checks if the defect can be solved or if the customer should receive a new final drive.

A customer can exchange an old final drive for money when buying a new one. The customer will receive a certain amount of money for the old final drive if the final drive can be reconditioned and reused.

All three processes start with the inspection of the final drive, this is why the first thing a mechanic does is making a diagnosis. The mechanic checks if the final drive has any visual damage, if it has been dissembled before and whether the final drive is mounted correctly.

When the problem is not directly visible the mechanic has to dissemble the final drive for further inspection. After the final drive is dissembled it is thoroughly cleaned. Firstly, the reduction and hydro side are dissembled and checked for defects. Both sides need to be secured with a nut and Circlip. It is important that the bearings are checked for movement. If the bearings can move this can increase the amount of wear patterns. The defect can also be the result from damaged components, this is why the gears and O rings have to be checked.

After everything has been inspected the findings about the hydro motor, reduction chamber and important components are noted. The mechanic orders new parts for the ones that are broken and/or damaged in order to repair the final drive.

After the final drive is repaired the mechanic still has to do some important actions. After the reparation the mechanic adds oil to the reduction side until the oil level is correct, tests the final drive on the test bench and fills in the test report.

During the test various aspects are checked. First the functionality is inspected, in the first and second gear the following things are tested; Whether the final drive moves freely to both directions, has a functioning brake and if it has any oil leakages. The values such as pressure (bar) and RPM (28L/min) are noted for both turning directions. Secondly, the state of the final drive is checked; are the assembly points of the final drive clean and/or damaged, is the state of the thread on the sprocket- and machine side sufficient, is the final drive filled with oil and are the hydraulic connection points sealed off with caps? Upon delivery of the reconditioned final drive the customer receives a test certificate will all findings.

Finally, the final drive is painted and after this step the final drive is ready to go to the customer.

Buying a new final drive is not always needed. We can recondition a broken final drive for the right price. Inform for all possibilities.

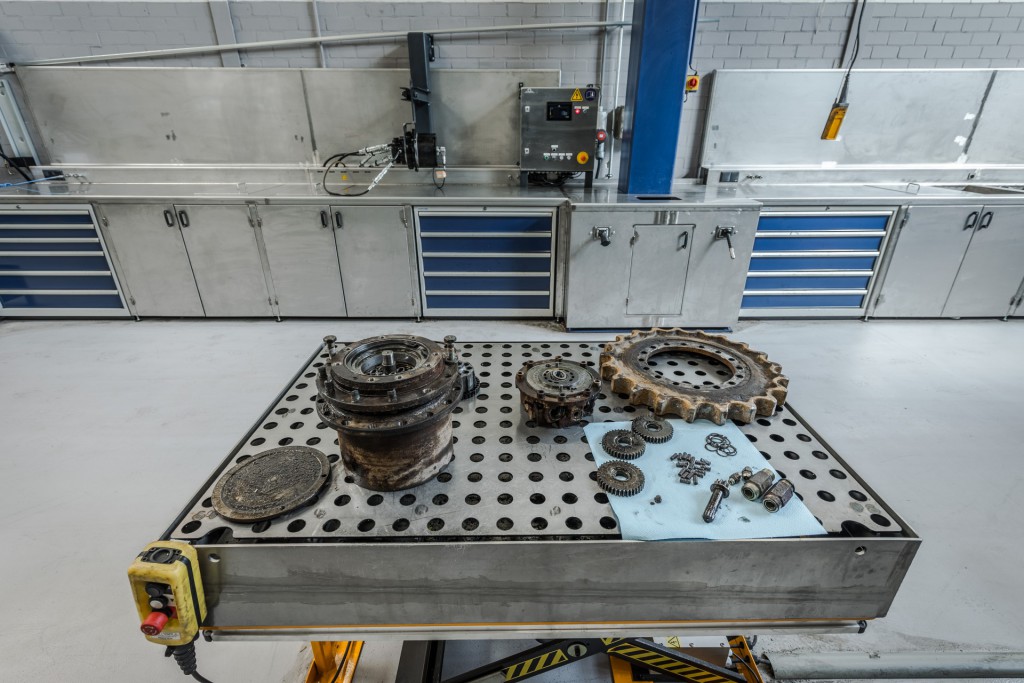

All final drives are reconditioned with specialized equipment in our own workplace. Below is a picture of the VTS workplace.

Other news